To ensure the proper functioning and longevity of your hydraulic bottle jack, as well as to guarantee safety during use, it’s important to follow some maintenance and safety guidelines.

For maintenance, regularly check for oil leaks6. A leak can not only affect the performance of the jack but also pose a safety risk. If you notice any oil stains around the jack, it’s time to have it inspected and repaired. Also, keep an eye on the hydraulic fluid level6. Low fluid levels can lead to reduced lifting capacity and inefficient operation. According to the manufacturer’s recommendations, replenish the hydraulic fluid in a timely manner.

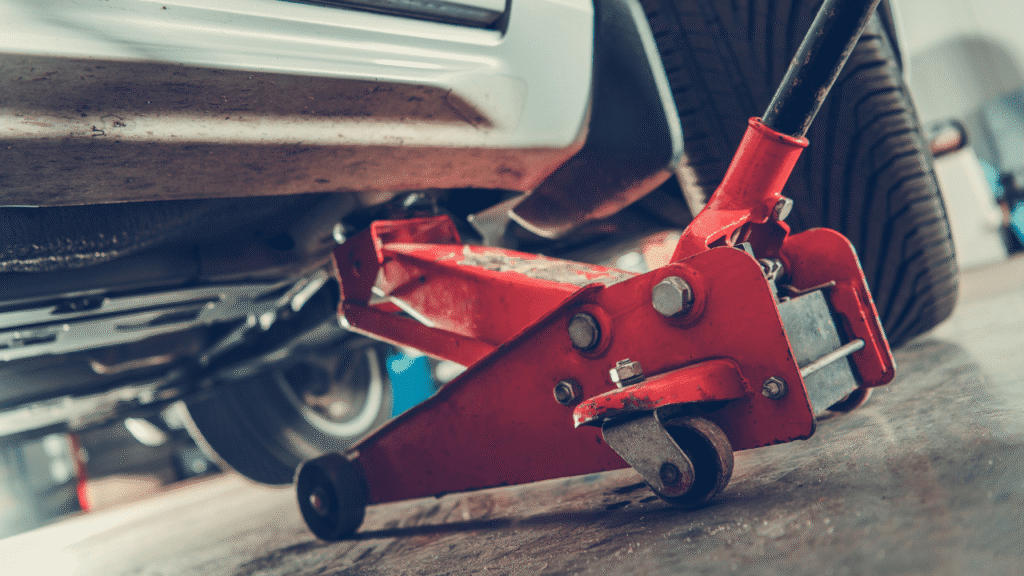

When it comes to safety, always use the jack on a flat and stable surface6. An uneven surface can cause the jack to tip over, resulting in serious accidents. Before lifting, make sure the load is centered on the lifting pad to distribute the weight evenly6. Never exceed the rated capacity of the jack6. Overloading can cause the jack to fail, and it’s extremely dangerous.

In addition, when using the jack, follow the manufacturer’s instructions carefully. Don’t try to modify the jack or use it in a way that is not recommended. After use, store the jack in a dry and clean place to prevent rust and damage. By following these maintenance and safety tips, you can make your hydraulic bottle jack serve you well for a long time while ensuring your safety.